The intention was to build a smoothly tapering wing with the following

features:

- No polyhedral.

- Add a 'D' box for torsional stiffness.

- Top and bottom rib capping.

- Ease the flat bottom, adding a slight turn up at the leading edge of the

ribs.

- Add ailerons.

- Add side mount (to fuse) bar to wing root.

|

|

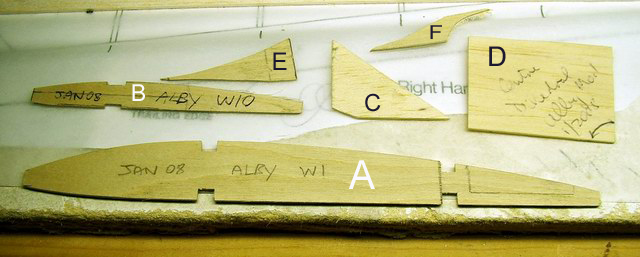

A - Plywood wing root template. Shaped approximately to rib W2. No

intention of using the rear spars!

B - Plywood wing tip template.

Shaped approximately to rib W10.

C - Right angle for checking ribs are installed vertically.

D - Root rib installation angle - less than as specified for the Albatross

which has a lot of dihedral.

E and F - Chocks used to shape the bottom sheet up to the rib leading

edge.

|

|

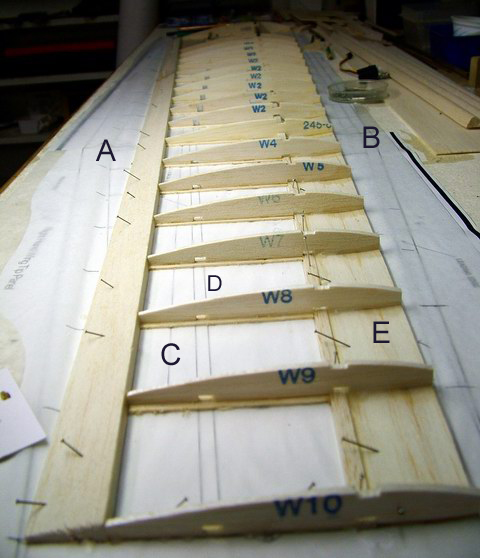

A and B - Notice the amount of original wing now excluded from the

construction.

C - Line indicating where the aileron will be cut from the completed wing.

D - Rear spar not used! Wing is to be 'D' boxed and rib-capped.

E - Bottom sheeting for 'D' box construction.

Notice the rib numbering. All the original ribs were used and just

reshaped using the templates (A and B above) to provide a smoothly

tapering wing. The 'Sandwich' technique was used to shape all the ribs at

the same time.

|

|

A - Bottom sheeting throughout near the wing root.

B - Brass tube epoxied between top and bottom main spars. The steel bar

(running through the tube) connects the two wings and transfers load

between the wing and fuselage.

C - One of two plywood shear transfer pieces either side of the brass

tube. This transfers wing connection load to the wing spars and sheeting.

D - These holes out to rib 12 allow a servo control wire to be installed.

The servo will be installed close to the aileron.

Can you spot a problem at ribs 10 and 11?

|

|

Another view of the wing with bottom sheeting, rib caps and servo cable

hole. |

| |